Prototyping and Product Development

Plastikon Industries, Inc specializes in product development and rapid prototyping services that serve numerous industries for their varying applications. Our in-house facilities in the US and Asia are fully equipped with the most sophisticated and innovative equipment and technology to ensure that our client’s needs and requirements are met.

In addition, we have a team of engineers and design staff with the knowledge and expertise of every industry. Therefore, we can provide our clients with the correct product development and prototyping services that best meet their requirements.

Prototyping Services by Plastikon Industries

We are dedicated to providing complete customer satisfaction, regardless of the size or complexity of your project. Our commitment to quality is evidenced in our products and services, and we strive for perfection in everything we do. It’s what our rapid prototype service is all about.

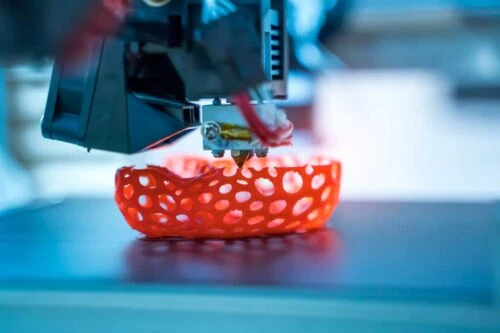

Rapid prototyping is the fast fabrication and manufacturing of a physical part, model, or assembly. Our team of exceptional and highly skilled designers uses different modeling programs to aid them in designing the product.

The modeling programs and CAD systems we use are as follows:

- CATIA

- MoldFlow

- SolidWorks

- UG

- Pro-E

These types of software help us determine the functionality and manufacturability of our client’s products. It’s part of the product development and product prototyping services that we have available.

Once the product is conceived, our rapid prototype machining services allow us to create a physical prototype of the part or assembly to be tested for functionality and durability. We utilize various state-of-the-art technology and traditional manufacturing processes depending on the design requirements and desired outcome.

Product Development to Achieve the Best Results

At Plastikon Industries, we strive to deliver customer satisfaction through product development and prototype services. Our offerings include visual proof of principle prototypes, form studies, and functionality. These services are available to help our clients thoroughly test their products and identify any potential flaws in the design before they go into production.

We understand that the success of a product can depend on its development process. That’s why we pay close attention to detail throughout the design process, from concept to finalization. Furthermore, we create samples using different methods first to know the best.

Our available methods include the following:

- Focused deposition modeling

- 3D printing

- Urethane casting

- Flexible stereo lithography

- Soft tooling

Our other process includes FMEA or Failure Mode & Effects Analysis, statistical process, lot traceability reports, and internal & supplier corrective action to ensure the product is ready to be manufactured. These will also let us know if there’s something wrong with the design to make room for more improvements while fixing any issues.

A Truly Customized Solution for Your Project’s Needs

We serve numerous industries to help them achieve their desired results. With our incredible product prototyping services and equipment, we can provide our clients with the best solutions for their project needs. Fortunately, our team of designers and engineers is well-versed in the various disciplines to help you create a customized solution for your business’s development.

Our secondary services are also designed to help you get the best end product and satisfaction from your project. These services include assembly, machining, patent development, design engineering, and fabrication. We have 10K and 100K cleanrooms for industries with high contamination requirements.

Choose Plastikon Industries for Your Prototyping Needs

We are committed to providing our clients with reliable, quality products and services through our rapid prototyping services. In addition, our sites are FDA registered as well as ISO certified. Rest assured that we can design and develop the products for your projects.

If you have any questions or concerns, don’t hesitate to contact us today. Our team is more than willing to help you out so that we can start making plans for your project’s needs.

General Capabilities

- 3D Printing

- Soft Tooling

- Form Study Prototypes

- Functional Prototypes

- Large Scale

- Proof of Principle Prototypes

- Scale Models

- Short Run Production

- Visual Prototypes

Secondary Services

- Assembly

- Fabrication

- Machining

- Product Design

- Product Development

- Patent Development

Reports

- Statistical Process

- Repeatability

- FMEAs

- Internal & Supplier Corrective Action

- Lot Code Traceability & Product Retains